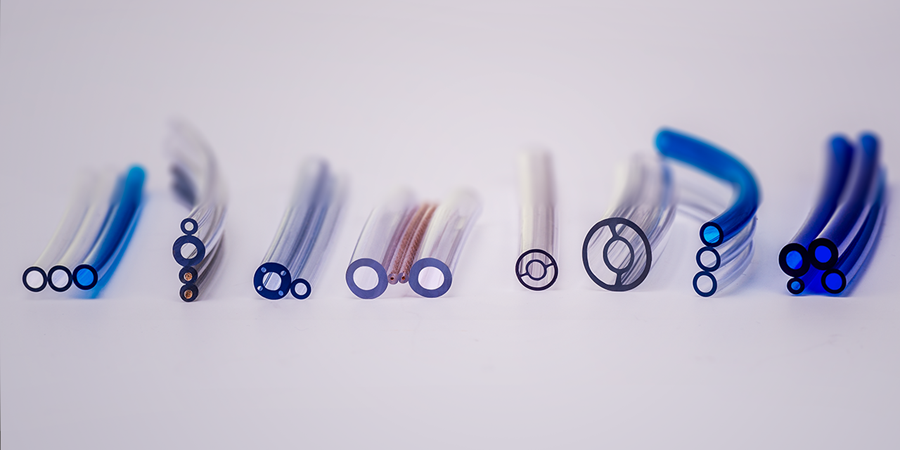

We can extrude tubing with high-performance materials, thin walls, tight tolerances, and complex geometries, whether you’re looking for quick-turn prototypes or full-scale production.

Our silicone extrusion solutions complement our thermoplastic tubing suite of products to provide a one-stop solution for your medical device needs.

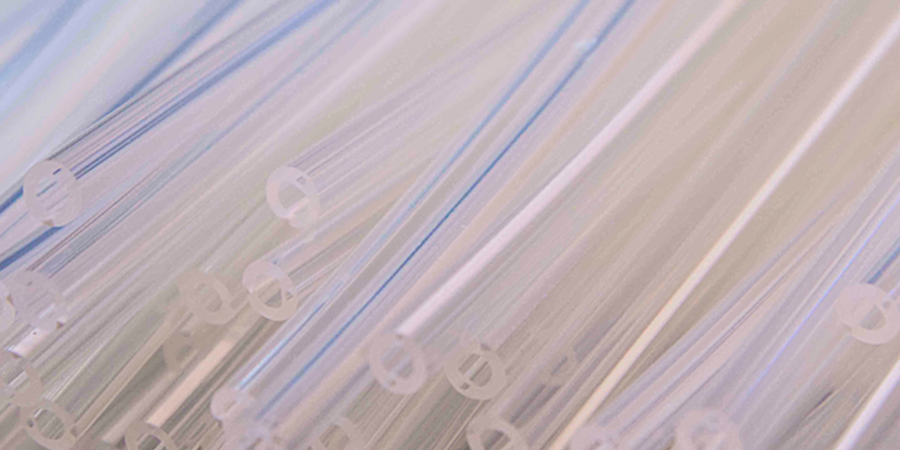

Used as a manufacturing aid for braid- or coil-reinforced catheter tubing, our core mandrels feature extremely tight tolerances to maintain consistent diameter and roundness for catheter manufacturing.

With tubing fabrication facilities in 5 countries, we offer a scalable, full-service package made to your precise specifications, including tubing, fittings, molded components, subassemblies, and assemblies.

Our fluid management product line features single-use plastic components for the medical and pharmaceutical industries, including bags, clamps, luers, caps, chambers, spikes, valves, and assemblies.

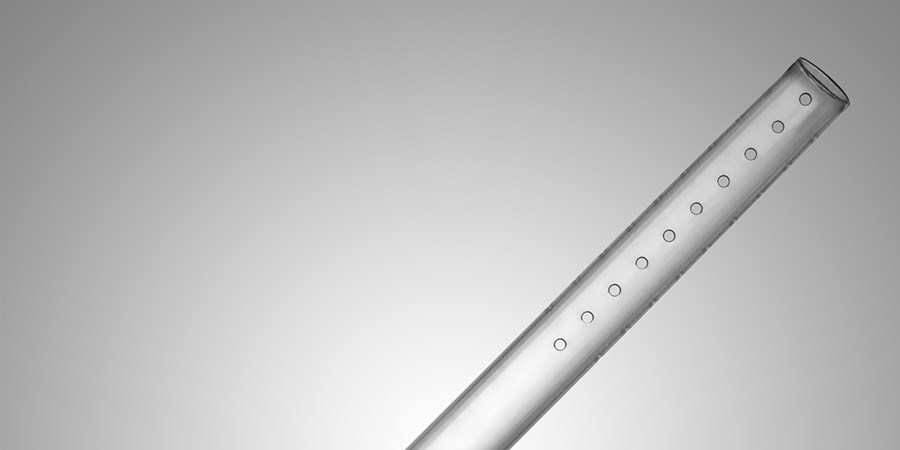

Lasers are high-precision machining instruments that cut micron-scale features in extruded tubing that enable specific medical applications, such as intravascular drug or stent delivery.

Polyetheretherketone (PEEK) is a high-strength, high-temperature thermoplastic with superior mechanical and chemical properties that are ideal for medical tubing and other demanding applications.

We’re a leading full-service manufacturer of high pressure braided tubing (HPBT) for vascular balloon inflation, contrast injection, vacuum procedures, and other interventional needs.