PEEK Tubing

Polyetheretherketone (PEEK) is a high-strength, high-temperature thermoplastic with superior mechanical and chemical properties that are ideal for medical tubing and other demanding applications.

PEEK Tubing

Polyetheretherketone (PEEK) is a high-strength, high-temperature thermoplastic with superior mechanical and chemical properties that are ideal for medical tubing and other demanding applications.

Spectrum understands the challenge of successfully processing high-performance and high-heat polymers for extruded tubing. PEEK is often the preferred polymer for high-performance materials for medical devices and other demanding market applications. Spectrum has the tools, technologies, and expertise to process PEEK and other high-performance thermoplastics for optimum function and longevity.

PEEK is a semi-crystalline thermoplastic that exhibits excellent chemical, mechanical, and thermal properties. PEEK is the material of choice for a variety of precision parts because of its high temperature, chemical resistance, durability, and potential for continuous use at HPLC pressure. Its load-bearing capabilities also make it a superior material for orthopedic, spine, and sports medicine implants.

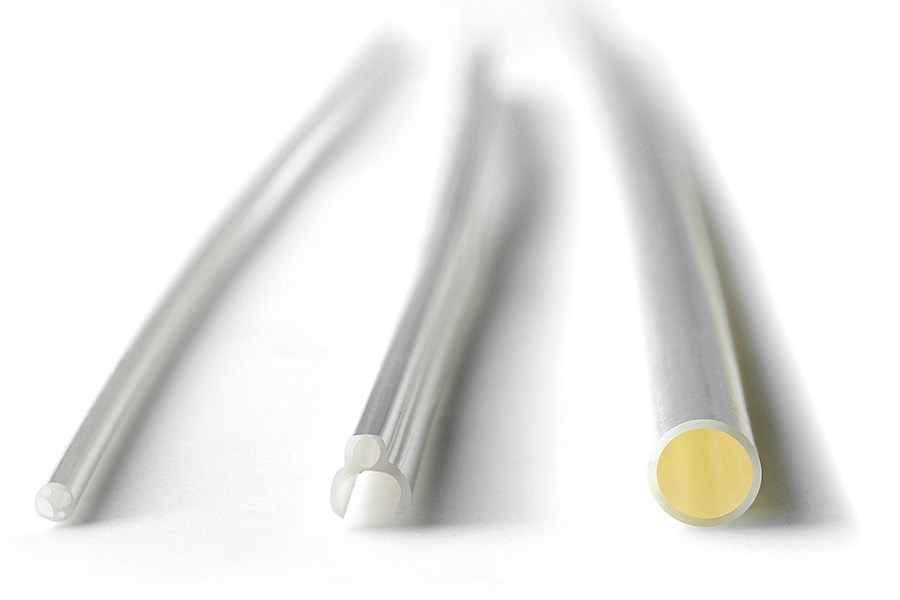

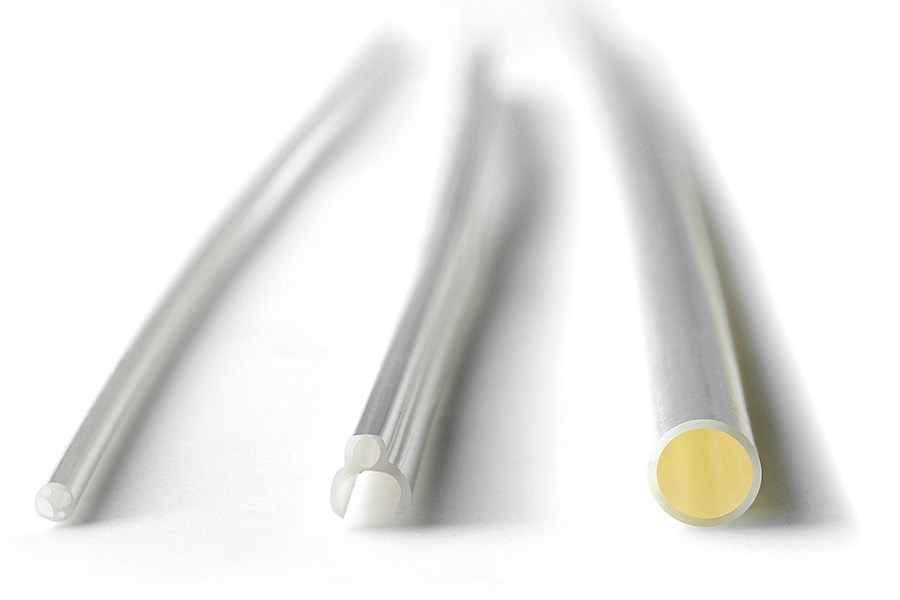

Spectrum’s experienced in-house material experts and extrusion engineers produce some of the most complex and custom profiles in PEEK on the market today, including:

PEEK can withstand the most rigorous physical and mechanical stresses. With a very low coefficient of friction, this material has high tensile strength and flexural properties, offers good push-ability and kink resistance in catheter applications, and can be manufactured to be radiolucent and radiopaque. Other key advantages of PEEK are:

PEEK is a preferred material for medical device applications that require high chemical and heat resistance, high tensile strength, flexural properties, and lubricity. It is especially popular for single or multi-lumen tubing for a variety of products, including catheters, and electro-surgical tools and instruments. For example, medical device applications include:

Secondary operations that Spectrum performs for PEEK extrusions include flaring, tipping, laser cutting, radiofrequency welding, ultrasonic welding, heat forming/tube bending, and hole punching.

Spectrum also provides automated and manual assembly in addition to sterile and nonsterile packaging, which shortens the customer’s supply chain, improves communication and quality, and delivers products to market faster.

PEEK tubing is widely used in minimally invasive medical devices, including catheters, endoscopes, and surgical instruments. Its biocompatibility and resistance to repeated sterilization make it ideal for applications requiring direct patient contact, while its excellent chemical resistance allows it to withstand harsh cleaning agents and sterilization processes common in medical environments.

PEEK is a solid option versus other common medical device materials like stainless steel and PTFE. At Spectrum, we have special machinery and processing technologies and knowledge/processes necessary to ensure proper performance of the parts we extrude. This includes the knowledge of how to achieve proper crystallinity levels for each of our customers unique needs and requirements for down-stream processing.

PEEK tubing offers controlled flexibility depending on wall thickness and diameter specifications. While maintaining its structural integrity, PEEK tubing can be manufactured with specific geometries and wall thicknesses to achieve the desired balance between flexibility and rigidity required for different medical and industrial applications.

PEEK tubing can withstand high-pressure applications up to 3,000 PSI, depending on wall thickness and diameter specifications. The material's excellent mechanical properties and dimensional stability under pressure make it suitable for HPLC (High-Performance Liquid Chromatography) applications and other high-pressure medical and industrial uses.

Our Glens Falls and Sandy sites have proven capabilities when extruding PEEK and are able to control crystallinity to fit the customer’s needs. For example, both sites possess the equipment and “know how”, and collaborate to ensure best outcomes for our customers. Most recently, SPG’s Glens Falls purchased a new state of the art MD extruder with improved temperature capabilities necessary to reach and maintain the proper processing of PEEK and other high temperature thermoplastics.

PEEK offers superior mechanical strength and higher temperature resistance compared to PTFE, making it better suited for structural and load-bearing applications. While PTFE excels in non-stick properties and chemical resistance, PEEK provides better wear resistance and maintains its mechanical properties at elevated temperatures, making it the preferred choice for demanding medical and industrial applications.

PEEK is extensively used in orthopedic, spinal, and dental implants due to its bone-like mechanical properties and excellent biocompatibility. Its strength-to-weight ratio, resistance to degradation in the body, and ability to be sterilized repeatedly make it an ideal material for long-term implantable devices and surgical instruments.

Product development is also accelerated through the use of Spectrum’s “off-the-shelf” PEEK extruded tubing, which is available via Spectrum Plastics Group’s webstore and includes:

Spectrum’s biocompatible PEEK filament is also an ideal material for injection-molded or additively-manufactured components and devices.

Although PEEK has been used for decades, its material properties continue to be engineered to provide specific characteristics for challenging end-use environments. Creating high-precision, tight-tolerance parts and products from PEEK requires experienced and knowledgeable material experts, extrusion engineers, and operators who are skilled with the latest advancements.