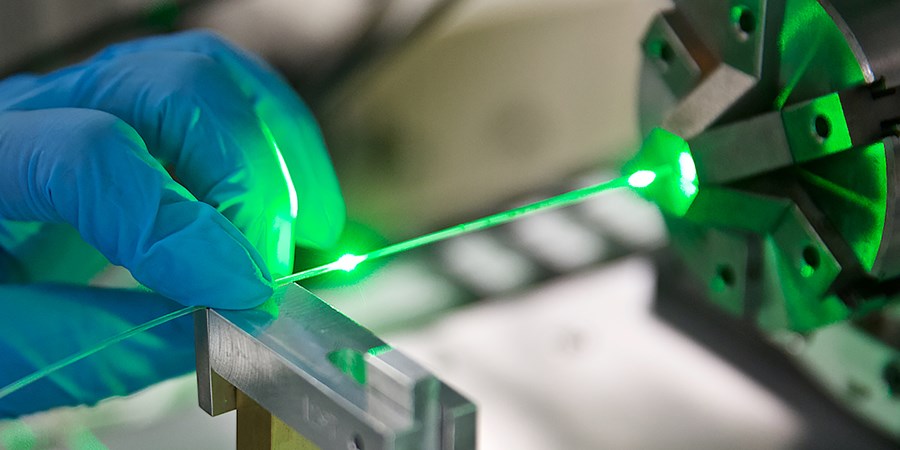

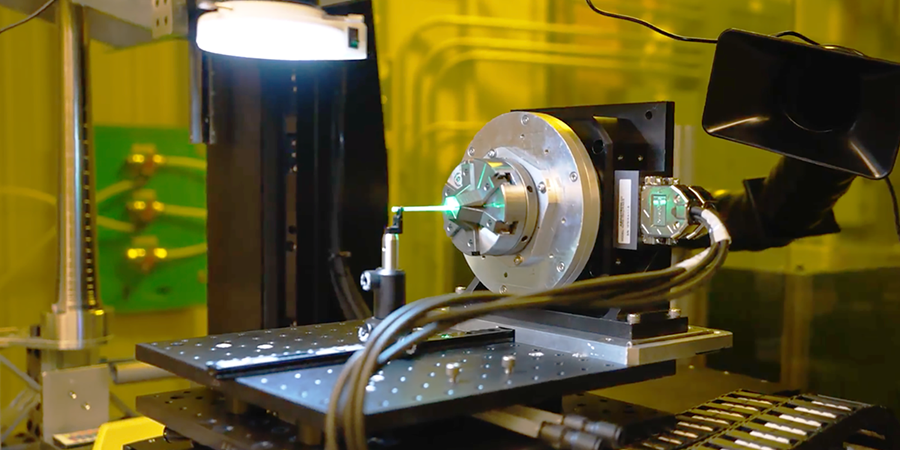

Our custom laser ablation processes selectively remove layers of substrate or coatings from materials or components with micron-level precision. We have ability to precisely remove virtually any polymer in medical device manufacturing.

Our laser systems provide high-precision laser cutting, with micron-level tolerances. We produce very small, complex features in a variety of materials, with methods such as direct write, trepanning, and mask projection, with no heat effects or material damage.

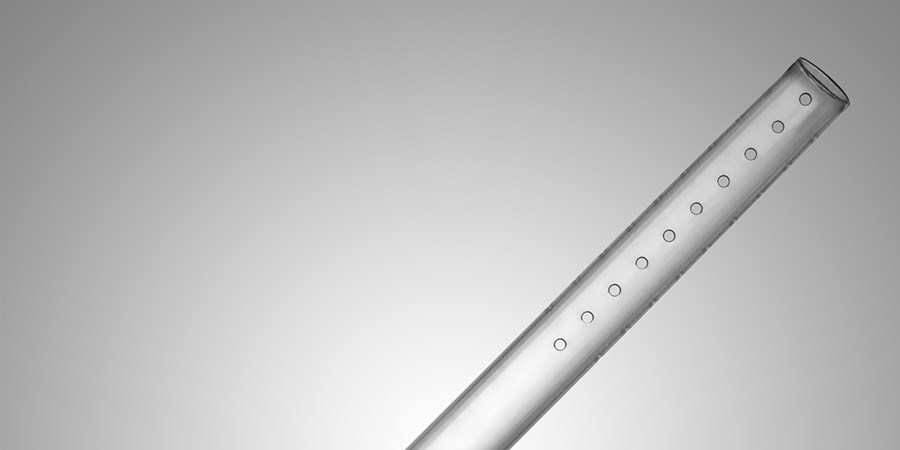

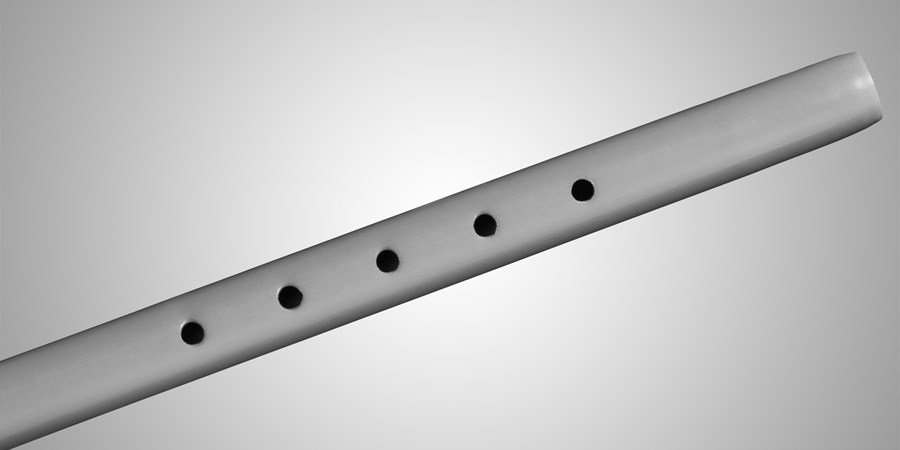

Our high-precision laser drilling technology produces small, complex features at micron-level tolerances, without heat effects or material damage. Our methods include direct write, mask projection, and more.

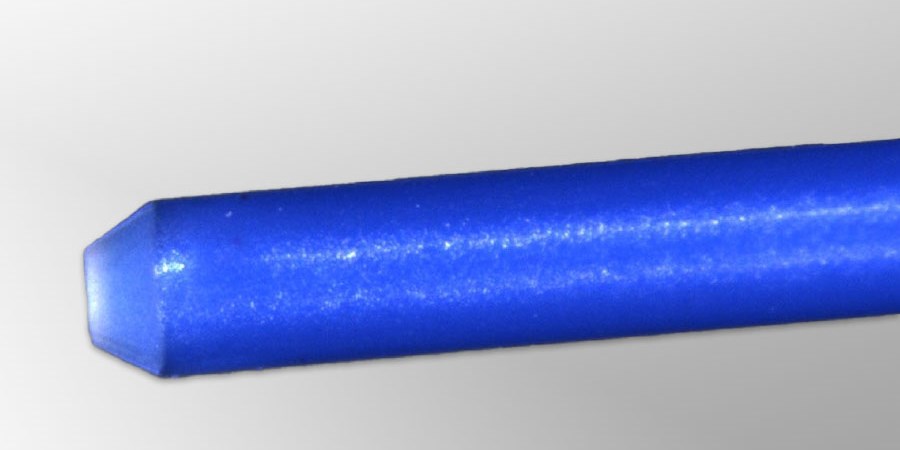

Our wire-stripping process removes sections of insulation or shielding without making physical contact with the conductor, enabling the processing of delicate wires and cables.

Ultra-fast lasers are in high demand because of their speed and precision—they can cut features as small as 0.0005 inches (13 microns) with high accuracy and no thermal damage.

Femtosecond lasers cut incredibly fine features with submicron accuracy, eliminating heat-affected zones and reducing the need for secondary finishing.

Tip-forming is the process of shaping the end of the catheter into a specific shape that enhances maneuverability. Spectrum engineers use a laser to form the tip; no heating and shaping is required.

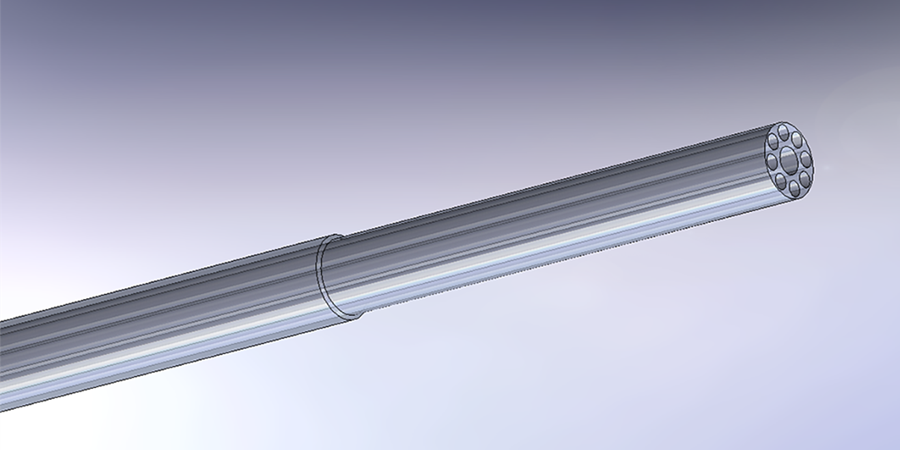

Laser cut hypodermic tubes (hypotubes) are small-diameter tubes that have been precisely cut using laser technologies. Hypotubes are commonly used in catheter assemblies.