Ablation

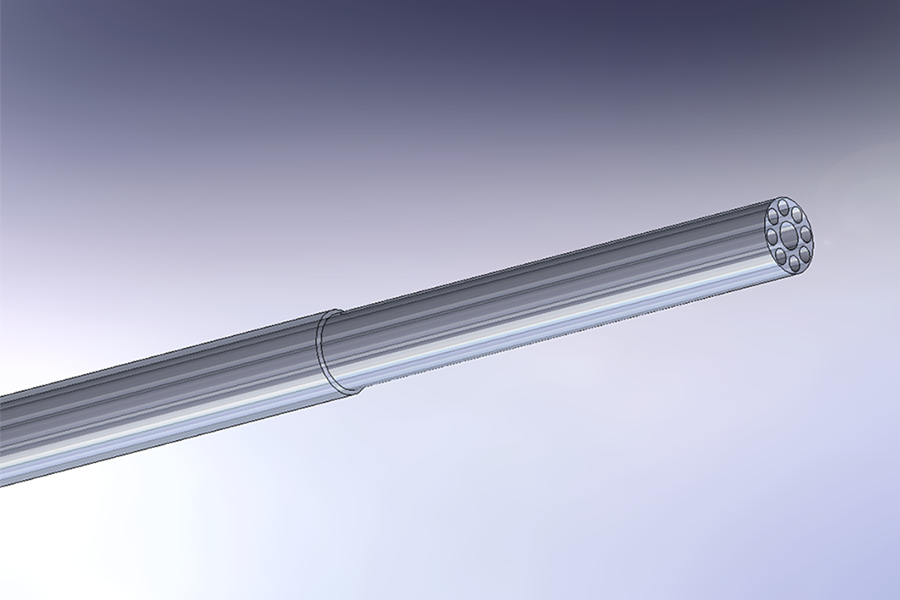

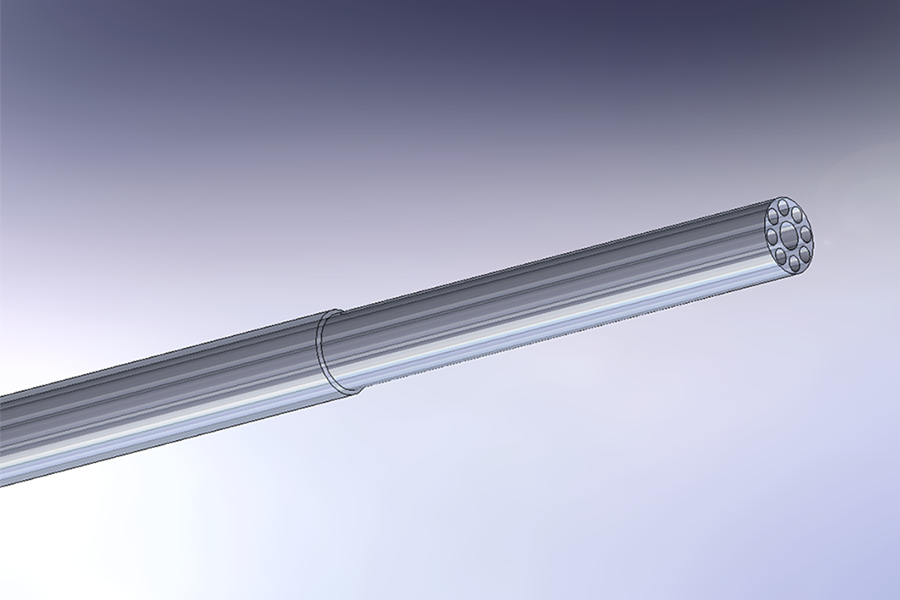

Our custom laser ablation processes selectively remove layers of substrate or coatings from materials or components with micron-level precision. We have ability to precisely remove virtually any polymer in medical device manufacturing.

Ablation

Our custom laser ablation processes selectively remove layers of substrate or coatings from materials or components with micron-level precision. We have ability to precisely remove virtually any polymer in medical device manufacturing.

Lasers can be programmed to ablate or “vaporize” material from surfaces at the micron level. Ablation selectively remove layers of substrate or coating from the surface of manufactured parts, with little or no negative thermal or structural impacts to the surrounding material. As a result, laser ablation is fast-becoming the technology of choice for medical device and other high-tech production needs.

Laser ablation can also create surface patterns and textures that enhance performance. For example, the surfaces of drug-eluting balloons can be shaped with lasers to create flow channels for drugs or to provide pathways for electrodes. Texturing can improve the performance of the coating on the balloon or the underlying surface.

Pulsed lasers are also used to correct variable wall thickness or remove material to improve performance parameters, such as flexibility. Ablation is also ideal for producing parts from materials that require non-traditional processing methods, such as nanomaterials and superconducting materials. It can also be used to determine the chemical levels and concentrations on a surface or place film for processing nanomaterials.

Laser ablation offers a level of controlled depth and micron-level precision unmatched by any other manufacturing method. The benefits of laser ablation lie in its accuracy and its versatility. The energy from the intensely focused laser beam is absorbed by the material in the targeted area, which breaks down the chemical bonds and vaporizes the material, with very little or no thermal damage along the edges, reducing or eliminating the need for secondary processing.

Laser ablation is controlled by raising or lowering the laser’s pulse length, wavelength, and intensity. Our approach starts with testing your material sample to evaluate removal efficiency and establish parameters for laser micromanufacturing and post-laser processing—this lets us make accurate recommendations for optimal quality, efficiency, and productivity. The testing process determines the ideal combination of wavelength, beam quality, pulse repetition, pulse duration, and rate to achieve your desired results.

Laser ablation increasingly is the technology of choice for high-tech component processing needs that traditional machining methods cannot achieve—enabling a wide variety of applications across many different industries.

Laser ablation in medical treatments utilizes precisely controlled energy delivery to selectively remove or modify tissue with minimal thermal impact to surrounding areas. The process involves transferring photon energy to target cells or materials, causing rapid vaporization without conventional cutting. Advanced parameter control enables practitioners to achieve specific therapeutic outcomes by adjusting wavelength, pulse duration, and energy density based on the absorption characteristics of the target material and desired clinical result.

Laser ablation offers significant advantages including non-contact processing to eliminate mechanical stress, contamination-free material removal without chemical solvents, and programmable parameter control for customized processing solutions. The technology provides exceptional repeatability across production runs while enabling selective removal of specific layers in multi-layer constructions. These capabilities deliver substantial manufacturing efficiencies through reduced processing steps and minimal post-processing requirements compared to traditional mechanical or chemical methods.

Laser ablation is typically performed during precision finishing stages of medical device manufacturing, after initial component formation but before final assembly or coating application. The process is essential when requiring selective exposure of underlying materials, creation of precise surface features, or modification of material properties in specific areas. Timing within the manufacturing sequence depends on whether ablation is creating functional features, removing excess material, or preparing surfaces for subsequent processing steps.

Quality in laser ablation processes depends on precise control of beam characteristics, material properties, and environmental conditions. Critical factors include laser wavelength selection matched to material absorption properties, pulse duration calibrated to minimize heat-affected zones, and power density adjusted for specific material removal rates. Process stability requires consistent material composition, controlled ambient conditions, and high-precision motion systems to maintain feature accuracy across production runs.