Drilling

Our high-precision laser drilling technology produces small, complex features at micron-level tolerances, without heat effects or material damage. Our methods include direct write, mask projection, and more.

Drilling

Our high-precision laser drilling technology produces small, complex features at micron-level tolerances, without heat effects or material damage. Our methods include direct write, mask projection, and more.

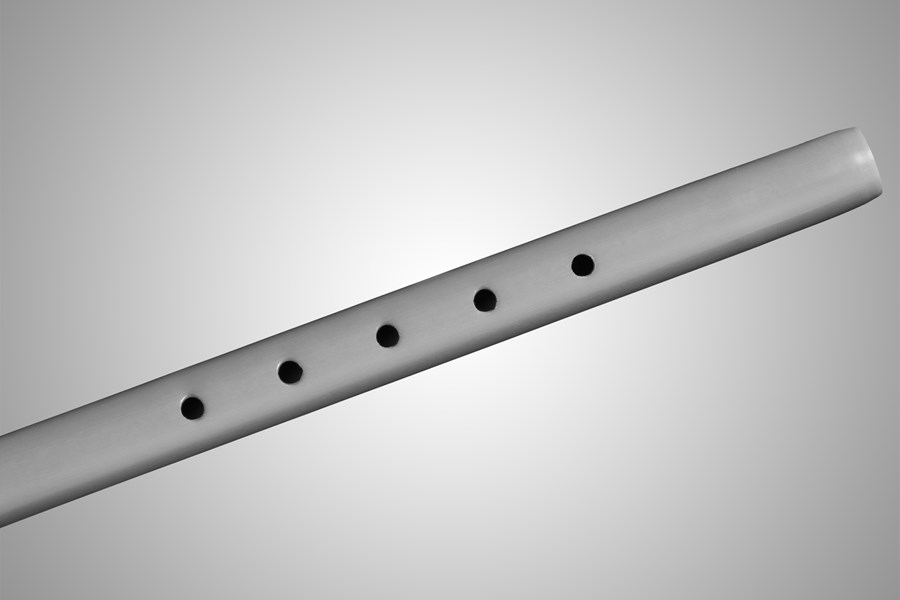

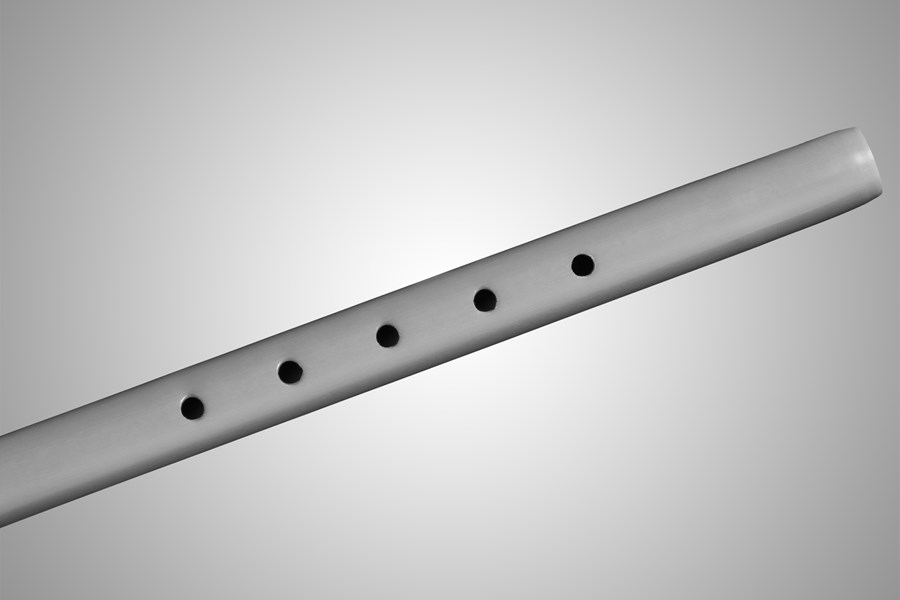

Many manufactured parts today call for microscopic features that can be created only with laser drilling. This highly adaptable, versatile, and reliable micromanufacturing process is used in a broad range of industries. We customize our laser manufacturing and post-laser processing to match your unique drilling needs, optimizing applications such as micro-holes, hole arrays, blind wells, and specialized portals.

Micron-scale holes (“micro-holes”) as small as 5 microns in diameter. These small-diameter holes can be laser-drilled (“micro-hole drilling”) in a variety of patterns with the highest precision. By using lasers, this drilling can be done without burrs or residual material that would potentially plug the holes, which is especially critical for embolic protection devices, infusion catheters, and drug-delivery catheters that rely on high densities of tiny laser-drilled holes to administer drugs at constant rates. In fact, laser drilling can create microscopic features that no other form of machining can deliver.

Laser drilling opens up a whole new realm of possibilities in manufacturing, allowing innovation to flourish. Laser micromachining can drill microscopic features in a wide variety of materials, including metals, polymers, and ceramic substrates. that no other type of machining technology can accomplish. Such high-precision applications include:

Many components used to manufacture medical devices are made from thermoplastic materials, which are sensitive to heat. Ultrafast lasers can drill holes quickly, with high precision and little to no heat damage.

Our lasers are carefully calibrated to avoid melting the edge material or creating other variances that can impact performance, as even the slightest melting can cause some holes to become blocked.

Thermoplastic materials are also flexible. If not held perfectly flat, that material may lay above or below the focal point of the laser, which can result in unwanted melting. Curved or variable surfaces are also challenging to drill and must be held securely.

Our teams use the latest precision-positioning systems, as well as our own proprietary set-ups and fixtures, to secure rounded components in place with no movement, resulting in consistent reliability and quality.

When designing a hole-drilling project, Spectrum Plastics Group engineers consider the type and thickness of material and hole specifications, including dimensions, hole depth, edge quality, and taper. They then match these, and production volume considerations, to the type of laser and laser wavelength (e.g., femtosecond laser pulses) needed, as well as the method of laser drilling.

Some methods of laser drilling include:

Outsourcing some or all of your manufacturing process means you no longer have to dedicate resources in-house. Often, working with a specialty contract manufacturer means getting superior expertise and quality control while eliminating unexpected costs.

Drilling processes can especially benefit from outsourced laser drilling. A specialized contract manufacturer, like Spectrum Plastics Group, will have the best laser technology, as well as industry and processes experts, compliance and control systems, and experience handling a wide range of applications. We provide contract manufacturing for laser drilling and other processes, whether for quick-turnaround prototyping or a full production run.

We often drill features that are too small to be seen by the naked eye. So our compliance and validation processes are continuously monitored and adjusted to maintain an effective quality management system, with tight tolerances in the sub-micron range.

Our tools for performing visual inspections on your parts and products include high-powered microscopes and specialized instruments for micro-measurement of linear dimensions, height, depth, and 3D profile.

Extra challenges can arise when micro-holes are required on the sloped or conical surfaces of balloons, which requires special fixturing. Multi-axis positioning controls and inline optical inspections are required during production to assure quality and repeatability. These methods have been developed here in-house and are especially valuable for customizing unique balloon shapes and sizes.

Laser drilling will continue to advance as companies propose more complex designs, materials, and added functionality. Often our best solutions result from working directly with the customer’s engineering teams, early in the design process, to create a customized laser-drilling process that pushes the technical limits of laser micro-machining.

Pulsed gas lasers can create consistent holes as small as 5 microns in diameter in certain applications. Holes of different geometric shapes at various angles are also possible, but round edges work best.

A typical laser feature has a maximum depth:diameter ratio of 10:1. (exceptions apply, not a rule of thumb, typically).