Femtosecond Lasers

Femtosecond lasers cut incredibly fine features with submicron accuracy, eliminating heat-affected zones and reducing the need for secondary finishing.

Femtosecond Lasers

Femtosecond lasers cut incredibly fine features with submicron accuracy, eliminating heat-affected zones and reducing the need for secondary finishing.

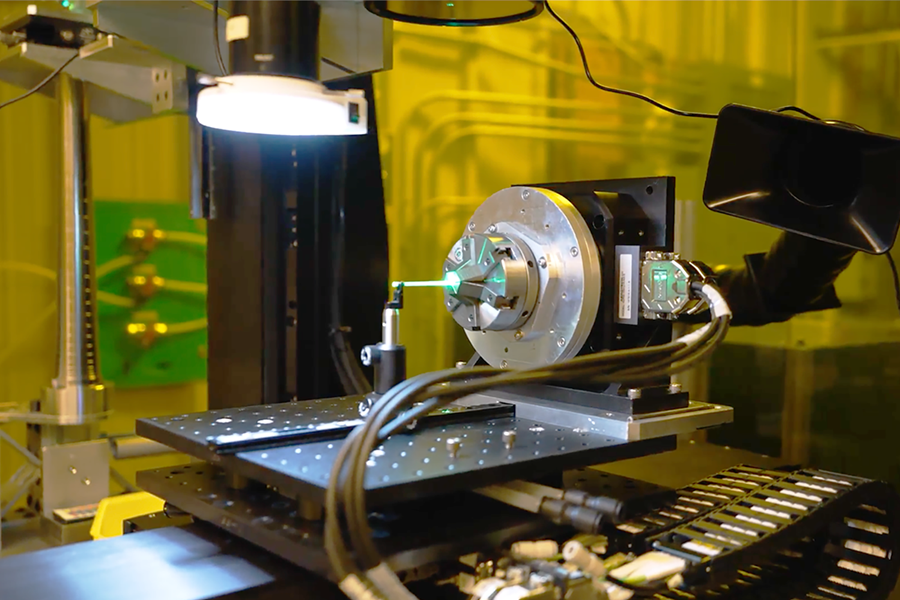

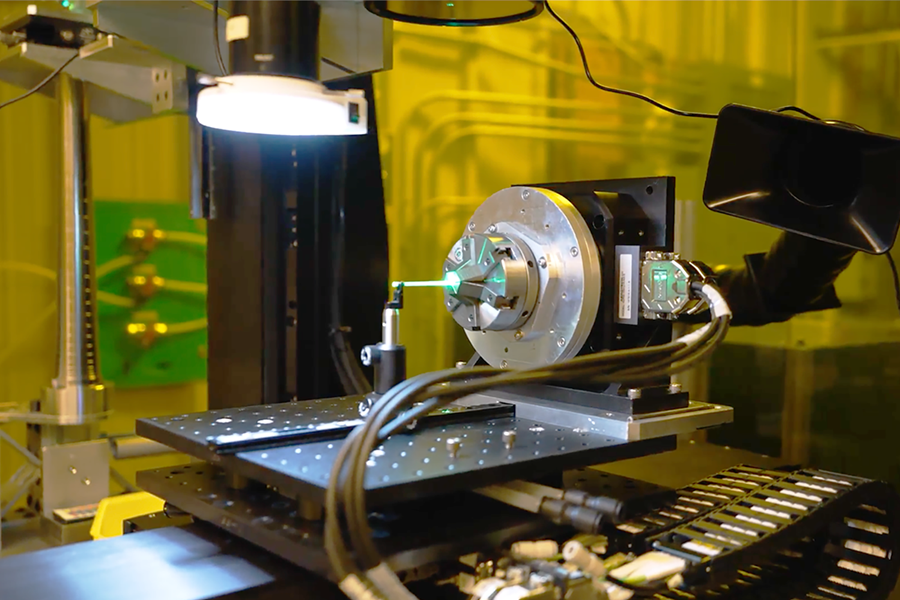

As products and components in the medical, life sciences, and microelectronics industries become miniaturized and more complex, with the need for extremely tight tolerances, manufacturers increasingly turn to femtosecond lasers for their micromachining needs. Features can be as small as a few microns, with submicron tolerances. In fact, some features can only be cut with femtosecond lasers, expanding design options for engineers and designers.

Femtosecond lasers are the fastest, highest-precision lasers in micromanufacturing today, cutting two- and three-dimensional features or structures on flat or curved surfaces. With femtosecond (1 fs = 10−15 s) pulses of laser light that are extremely well focused, these lasers can cut complex shapes with high dimensional accuracy. Because the laser pulses are so short, heat is not transferred beyond the material being removed, greatly reducing the occurrence of heat-affected zones (HAZ). This allows for more intricate features to be cut with less burring or discoloration, especially in sensitive materials or thin films.

Because of their superior peak power, femtosecond lasers can process nearly any type of solid material, including layered, mixed, laminated, or coated materials, with the highest quality and precision.

Popular uses of femtosecond lasers are:

One of the greatest benefits of femtosecond lasers is the reliability/repeatability of the micromachining of complex features and patterns with great accuracy. Process repeatability is maximized by the higher pulse-to-pulse energy stability femtosecond lasers provide. Features can be a small as a few microns, including 3D blind features with high-precision depth resolutions and clean, sub-micron kerfs. The lack of burring or redeposited debris reduces or eliminates most post processing needs. Rapid processing and the elimination of secondary finishing processes save time, reduces costs, and gets products to market faster.

Lasers can be automated to run 24/7 for large-volume or high-priority parts, maximizing production efficiency and speed to market.

Other operational benefits include:

Femtosecond lasers are transforming manufacturing by performing high-speed, high-precision material removal. In combination with automation, femtosecond lasers are transforming manufacturing by performing precision material removal, providing both exceptional quality and high volume throughput. Laser parameters such as pulse duration, pulse energy, pulse speed, and average power are material-dependent and customized as needed for individual projects. Features as small as 0.0005 inches (13 microns) can be laser-cut with high dimensional accuracy.